High carbon steel wire is popularly known as black wire. It is a drawn steel wire which is manufactured from quality wire rods with high carbon content. With a wide range of usage, black wire plays a vital role in many industries from automobile and construction to engineering industries.

As high carbon steel, it requires control of its fine pearlite structure to maintain high strength and achieve good drawability. Its typical applications include wire ropes, precision springs, bead wires and regular PC steel wires.

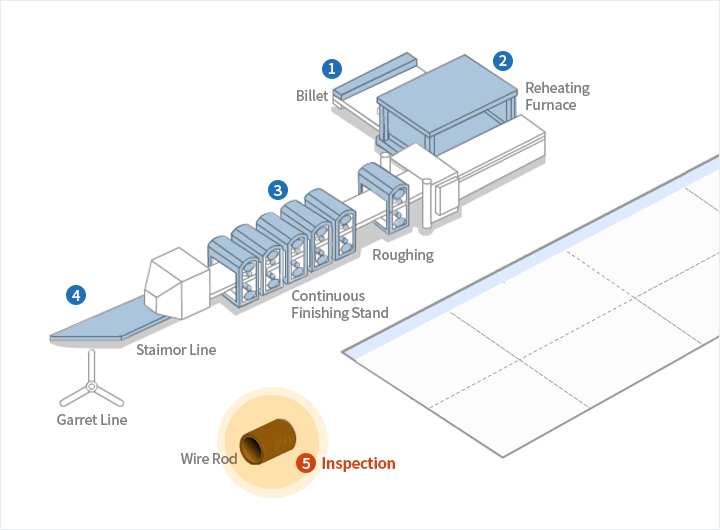

High Carbon Steel Wire (HTS) Rod

Steel Grade

82B

Size

10mm (diameter)